Understanding Boiler Slag

1 Understanding Boiler Slag By Rod Hatt Coal Combustion, Inc. Versailles, KY rod_hatt

WhatsApp)

WhatsApp)

1 Understanding Boiler Slag By Rod Hatt Coal Combustion, Inc. Versailles, KY rod_hatt

A pulverized coalfired boiler is an industrial or utility boiler that generates thermal energy by burning pulverized coal (also known as powdered coal or coal dust ...

The steel plant is a lean, green, recycling machine making new steel from recycled steel scrap. Enough iron and steel is recycled each year to save the nation 74% ...

Energy Balance of a CoalFired Power Plant in Condensing ... are upgrading constantly their coal power plant fleet ... and rate flow of feed water through HPH ...

Title: Analysis of Coal Ash Subject: SGS provides a complete range of laboratory testing for coal ash. Our stateoftheart labs can provide accurate data for ash ...

... Effect of Coal Properties and Operation Conditions on Flow Behavior of Coal Slag in Entrained Flow ... In the entrained flow gasifiers used in IGCC plants, ...

Fluidomatic Manufacturers, Exporters and Suppliers of Battery Making Machinery, Battery Recycling Plant Manufacturers India, Battery Breaker Machines Manufacturers ...

Selection of Coal for inclusion in Coal Blend in Coke Making. Blending of coals is necessary from economical point of view by reducing the percentage of high cost ...

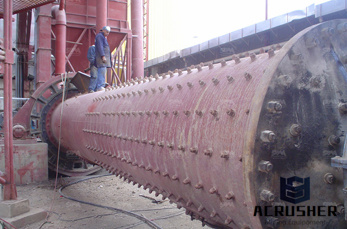

Coal Slag Flow Through Plant. ... is conducting pilot plant studies of a fixedbed slagging coal The molten slag drains into a water quench bath through a slag flow .

The charging system at the top of the furnace also acts as a valve mechanism to prevent the escape of gas, which is taken off through largebore pipes to a gas ...

Effect of coal properties and operation conditions on flow behavior of coal slag in entrained flow ... conventional coal plant ...

In entrainedflow gasifiers, fine coal feed and the oxidant (air or oxygen) and/or steam are fed cocurrently to the gasifier. This results in the oxidant and steam surrounding or entraining the coal particles as they flow through the gasifier in a dense cloud.

Combustion Optimization Through Air Flow ... reduced erosion due to lower flue gas velocities at full load and reduced risk of slag ... A coaltogas power plant ...

OM costs and forced outages at coal plants. Slag problems have plagued ... Minerals in coal will move through the flame ... Wall slag flows to the bottom of the ...

The process of producing energy using the gasification method has been in use for more than 180 years. In the early time coal and peat were used to power these plants.

Slag Control Treatment Program at EKPC Spurlock Station ... tubes and restrict gas flow to the point of furnace ... reference to coal and ash quality through the early

A. Abutment In coal mining, (1) the weight of the rocks above a narrow roadway is transferred to the solid coal along the sides, which act as abutments of the arch ...

SGS MINERALS SERVICES – T3 SGS 527 102013 COAL PHYSICAL TESTING COAL ANALYSIS SGS can provide the complete range of laboratory coal physical tests to meet

PHYSICAL AND COMPUTATIONAL STUDIES OF SLAG BEHAVIOR ... clear line of sight across the reaction section of an entrainedflow coal ... power plants are ...

Optimization of Tools to Manage Coal Properties and Plant ... Slag Flow Measurement Microbeam currently utilizes ... slag will be determined through careful ...

flow chart of the manufacturing process of slag cement XSM is a leading global manufacturer of crushing and milling equipment (flow chart of the manufacturing process ...

In the entrainedflow gasifiers used in integrated gasification combined cycle (IGCC) plants, the majority of mineral matter transforms to liquid slag on the wall of ...

6 oxygen ratio or through the use of a small oil flow down the lance. Fuel oil will also be injected down the lance to heat up the bath on start up following

Coal is cheap, plentiful and dirty as cheap as dirt, as plentiful as dirt, and as dirty as dirt since after all, coal is little more than dirt that burns ...

WhatsApp)

WhatsApp)