Ball mill Wikipedia

Working. In case of continuously operated ball mill, the material to be ground is fed from the left through a 60° cone and the product is discharged through a 30 ...

WhatsApp)

WhatsApp)

Working. In case of continuously operated ball mill, the material to be ground is fed from the left through a 60° cone and the product is discharged through a 30 ...

I133 SLURRY POOLING AND TRANSPO RT ISSUES IN SAG MILLS Malcolm Powell1 and Walter Valery2 1Head Comminution Group, Mineral Processing Research Unit,

Mar 14, 2007· Any handbooks/papers for the manual design of SAG/ball/rod mill foundations? We are doing a preliminary design only and don''t want to use finite element .

Web portal for buildingrelated information with a "whole building" focus provided by the National Institute of Building Sciences. Areas include Design Guidance ...

Replacement or spare pressure bowl for Szegvari batch type attritor mill. Unit fits Szegvari size 1S mill and features stainless steel contact parts, jacket for ...

SPM® Duralast® Fluid End System doubles the life of conventional SPM® fluid ends. Learn about the specifications and support services on our product page.

Mar 31, 2011· Author Topic: Trouble with Alaskan Mill, especially Mini Mill (Read 16576 times)

3M firestop solutions prevent the spread of fire, smoke and toxic gases, and are supported with world class training and 3M technical expertise. Learn more.

Tabtight professional, free when you need it, VPN service.

A stamp mill (or stamp battery or stamping mill) is a type of mill machine that crushes material by pounding rather than grinding, either for further processing or ...

The ® cut end mining hose is built for suction and discharge applications. Get instant access to our product overview and support information.

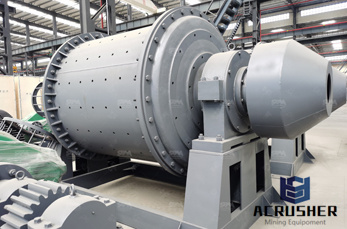

Grinding Mill/ Ball Mill Optimized Wear Life. Unicast Grinding Mill Parts combined provide a complete system for optimized wear life of grinding mill parts with cost ...

WhatsApp)

WhatsApp)