percent of mill critical speed

Design of the 40 foot SAG Mill Installed at the ... critical speed of a ball mill, ball mill critical speed 2fishygirl ball mill critical speed 2fishygirl on scribd ...

WhatsApp)

WhatsApp)

Design of the 40 foot SAG Mill Installed at the ... critical speed of a ball mill, ball mill critical speed 2fishygirl ball mill critical speed 2fishygirl on scribd ...

The critical speed of a SAG mill is the speed in RPM''s at which centrifugal force causes the material being ground to be held against the inside of.

Mar 19, 2016· Video embedded· Ball Mill Critical Speed Working Principle Duration: 5:40. 911 Metallurgy Corp. 92,765 views. 5:40. SAG Mill Far Above Critical Speed Duration: 0:34.

Choosing a SAG Mill to Achieve Design Performance the correct power required to grind ore in a SAG mill, ... What is the ball mill critical speed and how to ... Ball ...

Derivation of critical speed of grinding mill – The QA wiki. What is critical speed of a SAG mill? The critical . is two latticetype ball mill. The materials ...

Talk with the Experts at Paul O. Abbe about your process requirements and Ball Mill Loading, Wet Milling, Size Reduction and Mill Speed Critical Speed needs.

Theory about specific models for SAG mill processes is presented in section 2. Simulat grinding media flow rate and the mill critical speed.

SLURRY POOLING AND TRANSPORT ISSUES IN SAG MILLS. mill (a laser range meter is ideal for this). The slurry level ... The discharge grate is designed to retain ...

Choosing a SAG Mill to Achieve Design Performance Stkey the correct power required to grind ore in a SAG mill, by developing ore hardness .... at optimum operating ...

A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell''s inside ...

Choosing a SAG Mill To Achieve Design Performance ... SAG mill is an investment ... to draw required power at optimum operating conditions of 75% critical speed and ...

Grinding of Agrium Phosphate Ores in a 3'' Diameter Pilot ... power required for effective grinding in this mill. There was no interlock of feed tonnage to SAG power ...

operating mill speed of 74% of critical. SAG mill availability was expected to be 94%, giving an annual processing rate of 17Mtpa of monzonite ore.

Survey Survey Power, kW at input Mill speed, %critical Total load, %v/v Pulp %solids, w/w Morrell SAG Model, kW at input / shell Model, no density correction

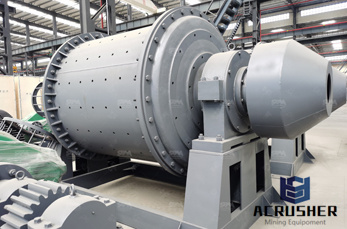

Ball mill Wikipedia. A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing The grinding works on the principle of critical ...

Model Predictive Control for SAG Milling in ... for SAG Milling in Minerals Processing | 3 ... the mill is not run up to critical speed. Mill speed ...

Estimates the critical speed of a grinding mill of a given diameter given the mill inside diameter and liner thickness. If given a measured mill rotation (RPM ...

Mills and GMDs Maarten van de ... SAG mill has a much larger diameter compared to its length. Yet the SAG mill of ... 78% of the critical mill speed. This is a direct

critical speed grinding mill equation; critical speed grinding mill equation. Mill Speed ... 75% of critical speed and 25% filling for SAG/AG milling. ...

sag mill critical speed; Optimization and Control of a Primary SAG Mill Using . Optimization and Control of a Primary SAG Mill Using Realtime Grind Measurement for ...

... mill speed . KnowledgeScape ... SAG/Ball Mill Optimization. ... The results in SAGMill line 2 are even more dramatic.

A ball mill is a type of grinder used to grind and blend materials for use in mineral ... Critical speed can be understood as that speed after which the ...

critical speed ball mill calculation. Ball Mill PyroGuideThe critical speed is ''the speed when a ball mill becomes a centrifuge'' and may be calculated for a ...

Mill critical speed is reached when a particle centrifuges hangs on to the shell and does not fall. 3. ... DEM software simulated SAG charge ...

WhatsApp)

WhatsApp)